Disability Management & Ergonomic Worksite Analysis: A Critical Link in Stay-at Work and Return-to-Work

Managing a workers’ compensation case is complex and poses a major challenge for all those involved in disability management. Federal and state labor laws, civil rights laws, health and safety regulations, medical privacy, opioid use, and current workers’ compensation reform issues make resolution of these cases difficult and trying for everyone.

Finding a method to resolve a case quickly, effectively, and fairly with consideration to both the employer and the employee’s needs is critical. PTs and OTs may find themselves called upon to perform an Ergonomic Worksite Analysis (EWA)—a critical link in managing and helping to resolve many workers’ compensation cases.

What Is Disability Management?

Disability management is the active process of minimizing the impact of an impairment (resulting from injury, illness, or disease) on the individual’s capacity to participate effectively in the work environment. It is a proactive process that enables labor and management to assume joint responsibility as proactive decision makers, planners, and coordinators of workplace-based interventions and services.

Disability management promotes disability prevention strategies, rehabilitation treatment concepts, and safe work-return programs. In addition, it is designed to control the personal and economic costs of workplace injury and disability—especially when it is integrated into an organization’s policies, procedures and strategies.

What Disability Management Is Not

Disability management is not only about claims management or the distribution of medical and cash payments. It is not just vocational rehabilitation or an expensive approach to control injury and disability costs. It is not an approach that relies solely on outside consultants. Nor is it a process that excludes the employer or the employee while offering a canned approach that is passive in nature or relies on the advice of attorneys.

Disability management is an essential part of business. It is a critical responsibility for the employer today and closes the loop on injury prevention should it fail. It is part of the continuum of work health management.

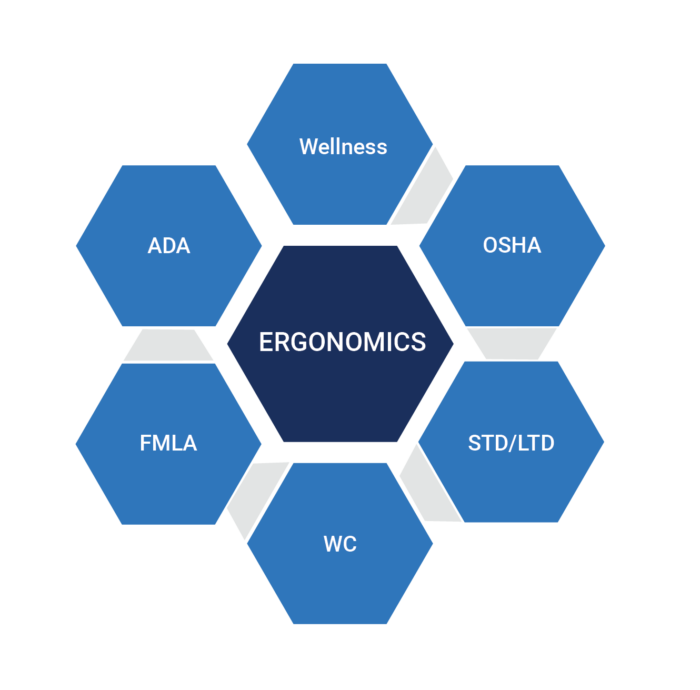

Figure 1. A model for the continuum of work health with a focus on ergonomics.

The Players

Integral to the process of disability management are its’ players. Key participants are:

- The injured worker

- The physician

- The employer and supervisor

- The RN or case manager

- The physical therapist and/or occupational therapist

- The vocational rehabilitation specialist

- The insurance adjuster and, in some cases, an attorney

Additionally, in today’s work injury management process, an ergonomist is also likely to play a critical role.

Each party exists to assist in resolving the case for the injured worker. Each offers multiple solutions to the problem, which must be carefully coordinated with all involved parties in a timely and effective manner. Documents and reports are often shuffled between providers, each trying to determine the fate of the injured worker and how the case will be resolved.

The Occupational Bond and Ergonomics

The most important goal in disability management is the restoration of the occupational bond between the employer and the employee. This goal should be shared by all the involved parties.

The occupational bond is the mutually beneficial relationship between the worker and the employer. It is multi-dimensional, involving the physical, psychological, social, and environmental aspects of work. The occupational bond is the worker relating to the employer through the daily routine of going to work, producing, and socializing. It is part of our everyday adult lives and provides a fulfillment unmatched by many of life’s rituals.

Ergonomics, in turn, is the relationship between the worker, the work tasks, and the work environment. As such, ergonomics becomes the critical link in restoring the occupational bond between the employee and the employer and a necessary part of the disability management process.

The Ergonomic Worksite Analysis provides essential information for the key players to make sound return-to-work decisions in managing the worker’s case. The EWA becomes a critical working document by which all involved parties can formulate the disability management plan.

Benefits of Ergonomic Worksite Analysis

The EWA establishes the relationship between the worker and the worksite by assessing the physical relationship between the worker, the work tasks, the tools and materials used, and the work environment. When performed correctly as part of workers’ compensation and disability management, the EWA accomplishes the following:

- Establishes the critical and essential job tasks

- Determines the physical demands required to perform the job

- Identifies the generic ergonomic risk factors of the job

- Recommends modifications to reduce hazards and the risk of re-injury

- Satisfies some (if not all) of the current state regulations and federal OSHA ergonomics guidelines: worksite analysis, hazard prevention and control, training, and medical management

Another major benefit of the Ergonomic Worksite Analysis is the ability to “match” the information obtained from the EWA with a work or functional capacity assessment, used often in managing workers’ compensation cases. These tools allow the key players to match the workers’ current work capacity with the required work capacity to perform the job in question.

The EWA allows for accommodation and modifications to be made in the work environment and facilitates goal setting for early return-to-work or transitional work program development. This, in turn, helps protect the employability of the injured worker by complying with the ADAAA in the employment of the qualified disabled worker through reasonable accommodation and worksite modifications.

Components of the Ergonomic Worksite Analysis

Since the Ergonomic Worksite Analysis is a relatively new tool used in the disability management process, the components may vary from evaluator to evaluator and the type of work performed—for example, is the worksite an office, manufacturing location, or healthcare facility?

In order to accomplish the goals identified, the following components should be included:

- Identifying subjective functional issues and return-to-work goals for the injured worker

- Utilizing an established job or task description

- Identifying the purpose of the job, the essential and marginal tasks, the tools and materials used, and any other pertinent issues of the job

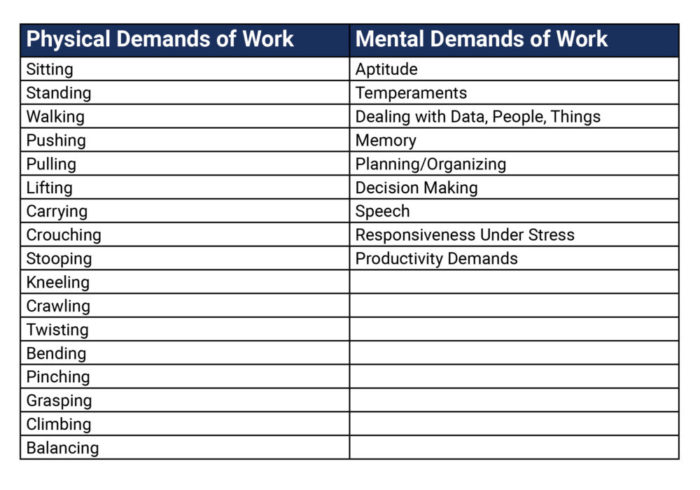

Time allocations from a well-documented source such as O*NET should be used to define the physical demands. This may also include interviewing the worker and supervisor for consensus. The demands should include, at a minimum, standing, sitting, walking, lifting (all heights), carrying, reaching, pushing, pulling, grasping/pinching, bending, reaching, twisting, kneeling, crouching, stooping, crawling, and handling. Mental demands such as organization, stress requirements, interactions, and others may be included. These demands are likely to be important as well, depending on the employee’s condition.

Table 1. The Physical and Mental Demands of Work (not all-inclusive)

Generic ergonomic risk factors need to be assessed. Consideration and documentation of forceful exertions, awkward postures, localized contact stresses, vibration, temperature extremes, repetitive motions, and prolonged static postures should be included in the EWA. The relationship between the worker, the risk factors, and the demands should be established by measuring heights and weights, forces, repetitions counted, and postures recorded to perform the job so that critical return-to-work decisions can be made.

Risk Management Recommendations

The evaluator performing the EWA must include risk management recommendations to assist the key players in the decision-making process. These include the following recommendations:

- Engineering changes in work design

- Administrative modifications to the job

- Work practice modifications

- Medical management

- Training and education

- Purchasing suggestions

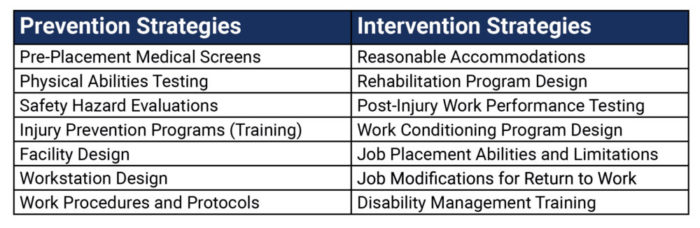

Cost-benefit considerations and practical solutions are strongly encouraged for improved compliance in the disability management process. The solutions provided for the injured employee can often lead to improvements in working conditions for other workers. The report should provide both prevention and intervention strategies, depending on the conditions in which it is performed.

Table 2. Prevention and Intervention Strategies Using Ergonomic Jobsite Analysis

Referrals, Service Provision, and Reimbursement Issues

Referrals can come from any of the involved players; however, the insurance adjuster, employer, or physician is most critical. The EWA is provided by a qualified person who understands the ergonomics of the workplace and possesses the skills and abilities to evaluate and document the components of the analysis. Such professionals may include (but not be limited to) a physical or occupational therapist, a certified ergonomist, or a loss control specialist.

As ergonomics becomes more prevalent in the working world and its use more valuable to the workers’ compensation insurer, the insurer is encouraged to assure the evaluators sent to the employer are well qualified to perform EWAs. Core competencies needed to perform an objective assessment including professional interview techniques and the skills to competently write an objective medical-legal report with the validity to hold up in court, if necessary.

Providers of the service should possess the appropriate credentials to perform such an essential analysis, such as CPE or CIE, and include a healthcare degree, such as a PT, OT, or Occupational Health RN. It is important to preserve the employee’s medical privacy, respect the EWA as a medical-legal document, and assure excellence in reporting.

Managing the Case with the Ergonomic Worksite Analysis

Managing the case with the EWA involves a few of the key players:

- The PT/OT defines the worker’s current capacity through the functional work capacity assessment.

- The professional ergonomist then performs the Ergonomic Worksite Analysis and submits the results to the physician, employer, and insurer.

- The physician reviews the report in order to decide the criteria under which to release the worker to return to work and determines the appropriate work capacity limits. The physician can also match the employee’s capacities and limitations with the job requirements through a transitional work program.

- The employer or supervisor implements the recommended engineering, administrative, and purchases required to perform the modified or accommodated work.

- The employee must be trained and educated in self-care through medical management and safe work practices regarding their condition and the job in question.

- The insurer works to close the case effectively once all decisions and actions are made with satisfaction.

Until we begin to use the Ergonomic Worksite Analysis regularly, we won’t truly realize the potential benefits this service has to offer, whether those be physical, psychosocial, or financial.

The physician should no longer guess at the modified work limits. The employer can set reemployment goals for the injured employee based on a solid foundation of work performance tasks to minimize the risk of injury for the worker and others in the same job class and prevent re-injury of the employee once back on the job.

The employee is integrally involved in their own rehabilitation plan and given back control through self-care and self-responsibility in the workplace. The insurance company can better anticipate claim costs and reserves necessary for the case and help to close numerous loopholes and reduce litigation.

The Ergonomic Worksite Analysis improves compliance with the ADAAA and other safety and labor issues, making it truly the critical link in the return-to-work process and an essential tool in disability management.

If you are interested in becoming a Certified Office Ergonomics Specialist so you can perform ergonomic worksite analysis onsite and remotely, you can learn more at the Worksite International Ergonomics Training Academy.

- Heller, A. (1998). Ergonomic jobsite analysis. Industrial and Occupational Ergonomics: Users Encyclopedia CD-ROM, University of Cincinnati.

- Heller, A. (2000). PT as ergonomist: The certification process. PT Advance.

- Shrey, D. & Lacerte, M. (1995). Principles and Practices of Disability Management in Industry. GR Press, Inc.

- US Department of Labor, Employment, and Training Administration. (1991). Dictionary of Occupational Titles, Volume I and II, Fourth Edition.